What Gives Stained Glass Its Color?

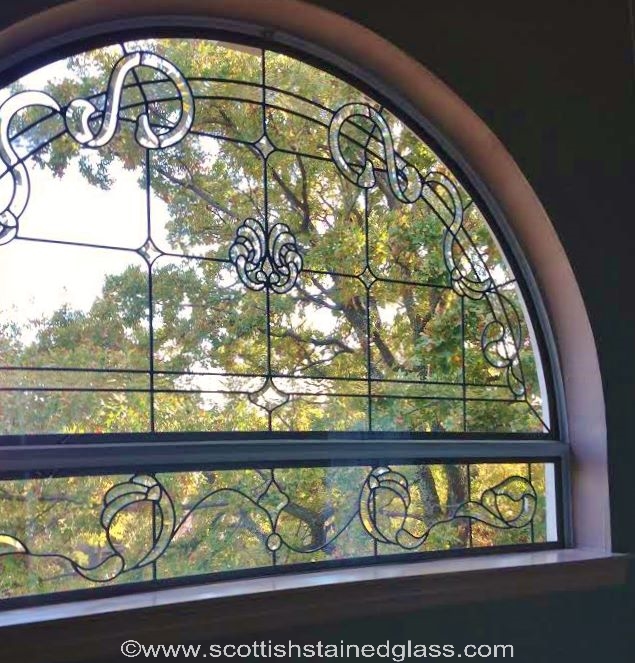

The stained glass manufacturing process can be facinating– from delicate glass painting to creating pieces with varying textures, there’s a lot of production that goes into every stained glass window. Customers looking into creating their own custom stained glass have a lot of options to choose from in regards to color, style, texture, and design. Have you ever considered what gives stained glass its color? The colored glass manufacturing process is very interesting and may actually surprise you. Here’s how you make colored glass:

The Stained Glass Color Production Process

Glass is created through a mixture of sand and scraps of broken waste glass, called cullet. Any glass that’s recycled for glass creation is referred to as cullet. When cullet and sand are sifted then placed into a furnace, a variety of additives are combined for glass creation. The furnace is heated to over 2900 degrees Fahrenheit in order for the cullet and sand to reach their melting points. The ancient Romans and Egyptians discovered that adding certain ingredients to this molten hot mixture could create colored glass. Gerber, an 8th-century chemist, discovered that metal oxides were the key to creating colorful glass. With today’s advancements in technology, we now utilize metal oxides, sulfides, and other compounds to create different colored glass options. Here are some of the more common additives required for developing colored glass:

- Cobalt oxide: blue/violet

- Gold chloride: red

- Cadmium sulfide: yellow

- Sulfur: amber/yellow

- Antimony oxide: white

- Chromic oxide: emerald green

- Uranium oxide: green/fluorescent yellow

Work with Fort Collin’s Number One Source for Colorful Stained Glass

Fort Collins Stained Glass is honored to be the number one source for colorful stained glass in the Colorado area. We love the science that goes into creating these beautiful works of art and are happy to share it. Contact us today!